-

Thermal Abuse Test Chamber

Heat abuse test box (thermal shock) series equipment is a variety of high temperature impact test, baking, aging test, one of the commonly used equipment, suitable for electronic instruments and meters, materials, electricians, vehicles, metal, electronic products, all kinds of electronic components in the temperature environment, the performance of the index and quality control

-

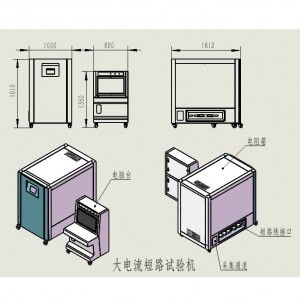

High quality temperature controlled battery short circuit tester

The temperature-controlled battery short-circuit tester integrates various battery short-circuit test standard requirements and is designed to meet the internal resistance requirements of the short-circuit device according to the standard. This allows for obtaining the maximum short-circuit current required for the test. Additionally, the design of the short-circuit device’s wiring must be able to withstand the impact of high current. Therefore, we have chosen an industrial-grade DC magnetic contactor, all-copper terminals, and internal copper plate conduit. The wide range of copper plates effectively improves the thermal effect, making the high-current short-circuit device safer. This ensures the accuracy of the test data while reducing the loss of test equipment.

-

High Current Battery Short Circuit Testing Machine KS-10000A

1、Advanced factory, leading technology

2、Reliability and applicability

3、Environmental protection and energy saving

4、Humanization and automated system network management

5、Timely and perfect after-sales service system with long-term guarantee.

-

Simulation of high altitude low pressure testing machine

This equipment is used for conducting battery low-pressure (high altitude) simulation tests. All the samples under test are subjected to a negative pressure of 11.6 kPa (1.68 psi). Additionally, high altitude simulation tests are performed on all the samples under test under low pressure conditions.

-

Customisable Battery Drop Tester

This machine is suitable for testing the free fall of small consumer electronic products and parts, such as mobile phones, lithium batteries, walkie-talkies, electronic dictionaries, building and apartment intercom phones, CD/MD/MP3, etc.

-

Battery explosion-proof test chamber

Before understanding what an explosion-proof test box for batteries is, let’s first understand what explosion-proof means. It refers to the ability to resist the impact force and heat of an explosion without being damaged and still function normally. To prevent the occurrence of explosions, three necessary conditions must be considered. By limiting one of these necessary conditions, the generation of explosions can be restricted. An explosion-proof high and low temperature test box refers to enclosing potentially explosive products within the explosion-proof high and low temperature test equipment. This test equipment can withstand the explosion pressure of the internally explosive products and prevent the transmission of explosive mixtures to the surrounding environment.

-

Battery combustion tester

The battery combustion tester is suitable for lithium battery or battery pack flame resistance test. Drill a 102mm diameter hole in the experimental platform and place a wire mesh on the hole, then place the battery on the wire mesh screen and install an octagonal aluminium wire mesh around the specimen, then light the burner and heat the specimen until the battery explodes or the battery burns down, and time the combustion process.

-

Battery heavy impact tester

The test sample batteries should be placed on a flat surface. A rod with a diameter of 15.8mm is placed in a cross shape at the center of the sample. A weight of 9.1kg is dropped from a height of 610mm onto the sample. Each sample battery should only withstand one impact, and different samples should be used for each test. The safety performance of the battery is tested by using different weights and different force areas from different heights, according to the specified test, the battery should not catch fire or explode.

-

High Temperature Charger and Discharger

The following is a description of the High and Low Temperature Charging and Discharging Machine, which is a high-precision and high-performance battery tester and a high and low temperature test chamber integrated design model. The controller or computer software can be used to set parameters for various battery charging and discharging tests to determine battery capacity, voltage, and current.

-

Constant temperature and humidity test chamber-Explosion-proof type

“Constant temperature and humidity storage test chamber can accurately simulate low temperature, high temperature, high and low temperature and humidity cycling, high temperature and high humidity, and other complex natural temperature and humidity environments. It is suitable for reliability testing of products in various industries such as batteries, new energy vehicles, plastics, electronics, food, clothing, vehicles, metals, chemicals, and building materials.

-

Battery Needling and Extruding Machine

KS4 -DC04 Power Battery Extrusion and Needling Machine is an essential testing equipment for battery manufacturers and research institutes.

It examines the safety performance of the battery through extrusion test or pinning test, and determines the experimental results through real-time test data (such as battery voltage, maximum temperature of battery surface, pressure video data). Through the real-time test data (such as battery voltage, battery surface temperature, pressure video data to determine the results of the experiment) after the end of the extrusion test or needling test battery should be No fire, no explosion, no smoke.

Battery

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

-

Top